|

Overhaul & Repair

Ferrotherm’s Repair Division operates an

ISO9002/AS9100 approved repair station. Our facility of over 17,000

sq/ft is totally separate from our new parts manufacturing and offers specialized

engineering, quality and production control personnel. Our extensive service

manual library includes TF34, TF39, T64, F100, F101, F404, F110, CF6-6, CF6-50,

CF6-80A, CF6-80C and others.

All repair work is done in-house operating on

a 24 hour, 3 shift cycle to give our customers the highest quality, lowest turn

time and competitive pricing. All specialized processes are accomplished in house,

are NADCAP or customer approved and include GTAW, EDM, ECG, FPI, vacuum brazing and

heat treat, hardness testing and metallurgical analysis. Our diverse customer

base includes GE engine services, Pratt & Whitney, Lockheed Martin, and

the United States Military, as well as various commercial carriers.

|

|

|

PART

NAME : Repaired Sheet Metal Air Seal Assembly

|

|

|

|

PART

NAME : Repaired LPT Shroud

|

|

|

|

PART

NAME : Repaired HPT Shroud Segment

|

|

|

|

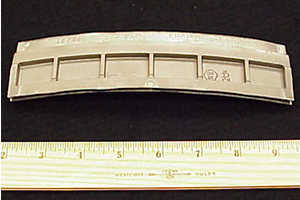

PART

NAME : Repaired Compressor Shroud

|

|

|

|

PART

NAME : Repaired Compressor Shroud

|

Ferrotherm's Repair Division has capabilities such as a dedicated Inspection department including ENSIP Certified FPI, CMM technology, a full weld-shop, and light machining to offer the highest quality and lowest turnaround time along with competitive pricing.

|